- Voltage: 100V

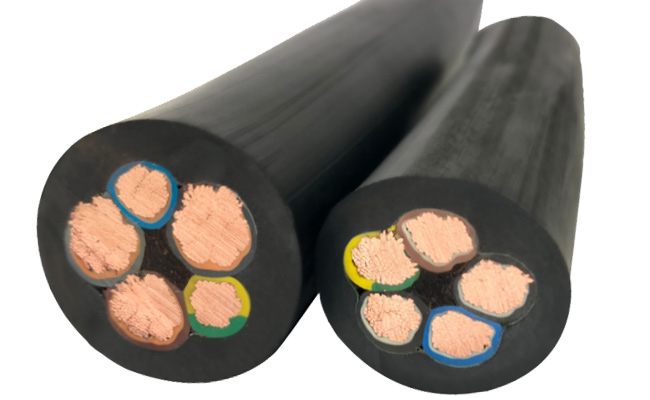

- Conductor: Class 6 Extra Flexible Copper

- Separator: PET (Polyester Tape)

- Outer Sheath: Rubber

- Sheath Color: Red/Black

- Standards: EN 50525-2-81, EN 60228, VDE 0282-6, BS 638

Flame Retardant according to IEC/EN 60332-1-2 - Temperature Rating

Fixed: -40°C to +85°C,

Flexed: -20°C to +85°C

Application&Installation of H01N2-D /H01N2-E Flexible Rubber Welding Cable

Application: These H01N2-D Welding Cable are used as a connection to welding robots in the automotive industry, shipyards, and for manually/automatically operated lines and spot welding. These cables are ideal for use as interconnecting battery cables or in battery storage systems. The robust cable structure makes them resistant to low and high temperatures, ozone and radiation, oils, acids, fats, and petrol.

Installation: Electrical supply of moving welding machines. This cable connects the welding equipment to the electrode holder. It is also recommended for all flexible links working under a low voltage U0/U 100/100V maximum. The flexible conductors and the reinforced sheath give the cables H01N2-D high flexibility.

H01N2-D Flexible Rubber Welding Cable Parameter

| No. of Cores | Cross-Sectional Area | Thickness of Insulation | Overall Diameter | Nominal Weight |

| mm2 | mm | mm | Kg/Km | |

| 1 | 10 | 2 | 9 | 146 |

| 1 | 16 | 2 | 10 | 204 |

| 1 | 25 | 2 | 11.5 | 290 |

| 1 | 35 | 2 | 12.5 | 384 |

| 1 | 50 | 2.2 | 14.5 | 535 |

| 1 | 70 | 2.4 | 16.5 | 716 |

| 1 | 95 | 2.6 | 18.5 | 943 |

| 1 | 120 | 2.8 | 20.5 | 1235 |

| 1 | 150 | 3 | 23 | 1556 |

H01N2-E Flexible Rubber Welding Cable Parameter

| No. of Cores | Cross-Sectional Area | Thickness of Insulation | Overall Diameter | Nominal Weight |

| mm2 | mm | mm | Kg/Km | |

| 1 | 120 | 1.8 | 18.5 | 1195 |

| 1 | 150 | 1.83 | 21.323 | 1485 |