- Voltage: 100V/450V

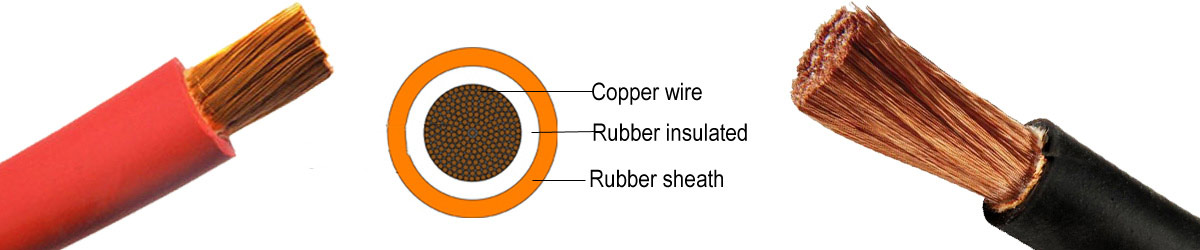

- Conductor:

1. BS Standard 16mm2~95mm2: Class 6 extra flexible

2.BS Standard 120mm2 and above: Class 5extra flexible - Insulated: EPR(Ethylene Polypropylene Rubber)

- Separator: PET(Polyester Tape )

- Sheath: HOFR(Heat and Oil Resistant and Flame Retardant)

- Outer Sheath: Black and Orange

- Standard: IEC60245, ASTM, VDE, DIN etc.

- ASTM Standard AWG Size: 1AWG, 2AWG,4AWG, 6AWG, 8AWG

- Temperature Rating: Flexed: -20ºC to +85°C

Application of the welding cable

The welding cable used for the transmission of high currents from the electric welding machine to the welding tool. Suitable for flexible use under rough conditions, on assembly lines and conveyor systems, in machine tool and motor car manufacturing, shipbuilding, for manually and automatically operated line and spot welding machines.

BS Standard Copper Conductor Welding Cable Parameter

| Conductor Class | No.of Core | Cross-sectional Area (mm2) | Total Radial Thickness of Covering (mm) | Nominal Overall Diameter (mm) | Nominal Weight (Kg/Km) |

| 6 | 1 | 16 | 2 | 9.7 | 215 |

| 6 | 1 | 25 | 2 | 11.2 | 305 |

| 6 | 1 | 35 | 2 | 12.4 | 400 |

| 6 | 1 | 50 | 2 | 14.3 | 587 |

| 6 | 1 | 70 | 2.2 | 16.3 | 775 |

| 6 | 1 | 95 | 2.4 | 18.6 | 1040 |

| 5 | 1 | 120 | 2.6 | 20.3 | 1256 |

| 5 | 1 | 150 | 2.8 | 22.6 | 1360 |

| 5 | 1 | 185 | 3 | 24.7 | 1875 |

ASTM Standard Rubber Fexible Welding Cable Parameter

| (AWG) | Nominal stranding | Nominal overall diameter | Approx. net weight | ||

| AWG | mm | inch | mm | (LBS/1000ft) | |

| 6 | 259/30 | 259/0.254 | 0.43 | 10.92 | 152 |

| 4 | 418/30 | 418/0.254 | 0.475 | 12.07 | 215 |

| 2 | 646/30 | 646/0.254 | 0.54 | 13.72 | 296 |

| 1 | 836/30 | 836/0.254 | 0.58 | 14.73 | 360 |

| 1/0 | 1032/30 | 1032/0.254 | 0.615 | 15.62 | 424 |

| 2/0 | 1290/30 | 1290/0.254 | 0.655 | 16.64 | 513 |

| 3/0 | 1672/30 | 1672/0.254 | 0.72 | 18.29 | 644 |

| 4/0 | 2066/30 | 2066/0.254 | 0.78 | 19.81 | 824 |

H01N2-D/H01N2-E Class6 Flexible Welding Cable

- Voltage: 100V

- Conductor: Class 6 Extra Flexible Copper

- Separator: PET (Polyester Tape)

- Outer Sheath: Rubber

- Sheath Color: Red/Black

- Standards: EN 50525-2-81, EN 60228, VDE 0282-6, BS 638

Flame Retardant according to IEC/EN 60332-1-2 - Temperature Rating

Fixed: -40°C to +85°C,

Flexed: -20°C to +85°C

Application: These H01N2-D/E Welding Cable are used as a connection to welding robots in the automotive industry, shipyards, and for manually/automatically operated lines and spot welding. These cables are ideal for use as interconnecting battery cables or in battery storage systems. The robust cable structure makes them resistant to low and high temperatures, ozone and radiation, oils, acids, fats, and petrol.

H01N2-D Flexible Rubber Welding Cable Parameter |

||||

| No. of Cores | Cross-Sectional Area | Thickness of Insulation | Overall Diameter | Nominal Weight |

| mm2 | mm | mm | Kg/Km | |

| 1 | 10 | 2 | 9 | 146 |

| 1 | 16 | 2 | 10 | 204 |

| 1 | 25 | 2 | 11.5 | 290 |

| 1 | 35 | 2 | 12.5 | 384 |

| 1 | 50 | 2.2 | 14.5 | 535 |

| 1 | 70 | 2.4 | 16.5 | 716 |

| 1 | 95 | 2.6 | 18.5 | 943 |

| 1 | 120 | 2.8 | 20.5 | 1235 |

| 1 | 150 | 3 | 23 | 1556 |