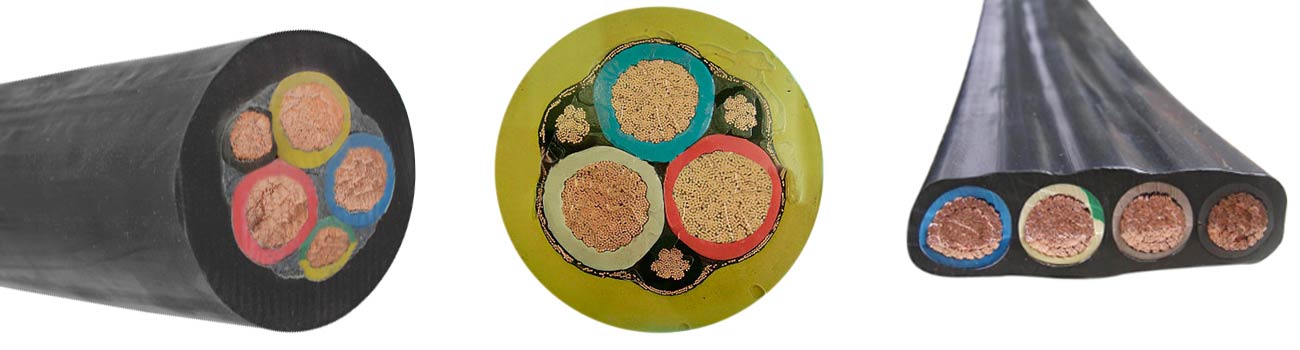

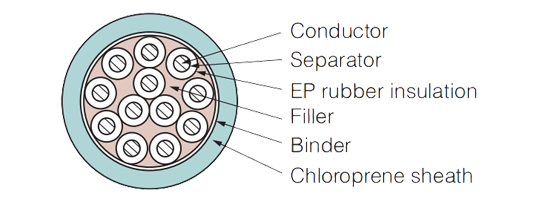

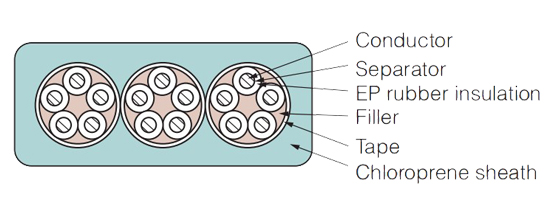

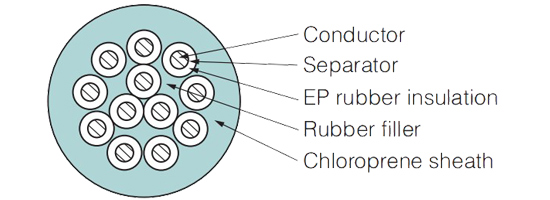

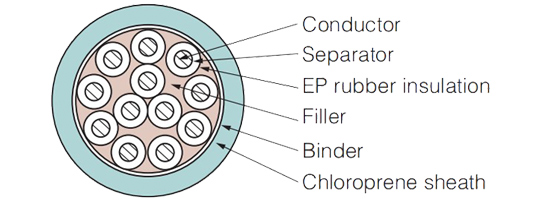

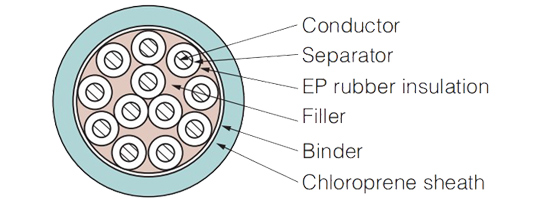

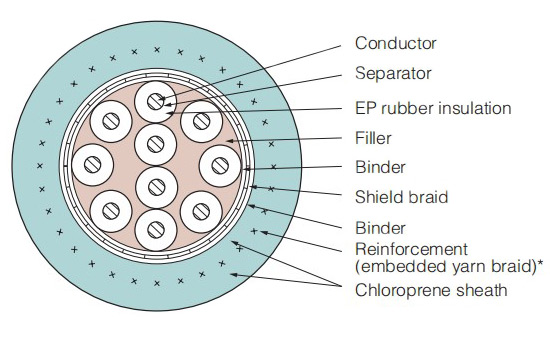

Structure of PNCT Cable

- Voltage: 300/500V, 450/750V, 600/1000V, 3kv, 6kV, 10kV

- Type: PNCT-F or R/2PNCT/2PNCT-SB/3PCNT

- Conductor: Copper(Class2,Class3,Class4)

- Insulated: EPR/ EPDM/ CPE/ Nitrile rubber/Silicone rubber

- Inner/Outer Sheath: CR/PCP/CSP/ CPE/Nitrile rubber/ Silicone rubber

Application Ranges of PNCT Cable

- The cable is mainly used for a mobile machine such as:

- Hoist &hoppers

- Unloader&Reclaimer

- Crane&Elevator

- Impact Resistance

- Stacker & Reclaimer

- Shield machine

More Ruber Cable Products

- – H07RN-F Cable

- – PNCT/2PNCT/3PNCT Cable

- – Submersible Pump Cable

- – Rubber Welding Cable

- – H01N2-D Welding Cable

- – SJO/SJOOW/SOOW Cable

- – Reeling/Crane Cable

- – Mining Rubber Cable

- – H07ZZ/H05RR-F Cable

CUR-2PNCT Cable Used for Festoon System

– High flexibility and bending resistance. (however, not suitable for applications

wherecables are subjected to lateral pressure, such as carrier drum system)

SK-2PNCT Cable Used for Festoon System

– High flexibility and bending resistance. (however, not suitable for reeling system) – More efficient cable installation because of itssmaller bending radius than those of round cable.

CAR-2PNCT Cable Used for Carrier Drum System

– High resistance to lateral pressure.

– Reduced cable corkscrewing by making rubber sheath solidal structure.

– Robust type of chloroprene is used as a sheath.

RE-2PNCT Cable Used For Reel System

– High resistance to lateral pressure, tension, and bending.

– Small-size conductors have steel wires in addition to copper wires to increase the kink resistance and tension resistance.

– Robust type of chloroprene is used as a sheath.

H-2PNCT Cable Used for Reel System

– High resistance to lateral pressure and wear.

– Robust type of chloroprene is used as a sheath.

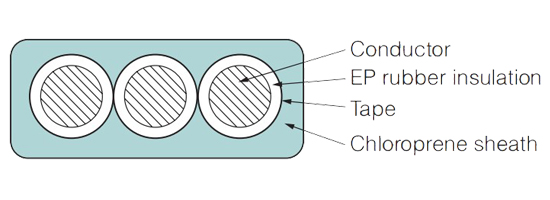

TOR-2PNCT Cable Used for Torsion System

– High torsion resistance.

– Improved slipping performance between cores by individually taping on each core.

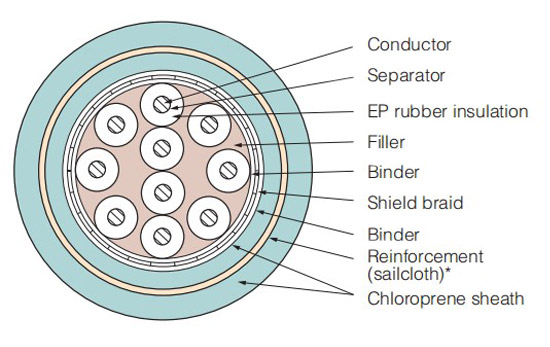

600V 3PNCT-SB/600V CUR-3PNCT-SB

- Your Content Goes HereStandards: JIS C 3327, Japan’s Electrical Appliance and Material Safety Act, Technical Standards for Electrical Equipment

- Rated Voltage: AC 600V

- Rated Temperature: 80 degrees C

- Test Voltage: : 3000V / 1 minute

- Feature: High flexibility and impact resistance

- Application: Festoon System and Lift System

600V 3PNCT-SB Cross-section

600V CUR 3PNCT-SB Cross-section

600V 3PNCT-SB, 600V CUR-3PNCT-SB Parameter Data

| No .of | Size | Conductor | Insulated Thickness | Thickness of Shield Braid | Sheath Thickness | |

| Cores | (mm2) | Construction(No./mm) | Outer Diameter(mm) | (mm) | (mm) | (mm) |

| 2 | 2 | 37/0.26 | 1.8 | 1.2 | 0.3 | 0.5 |

| 3 | 2 | 37/0.26 | 1.8 | 1.2 | 0.3 | 0.5 |

| 4 | 2 | 37/0.26 | 1.8 | 1.2 | 0.3 | 0.5 |

| 5 | 2 | 37/0.26 | 1.8 | 1.2 | 0.3 | 0.5 |

| 6 | 2 | 37/0.26 | 1.8 | 1.2 | 0.3 | 0.5 |

| 10 | 2 | 37/0.26 | 1.8 | 1.2 | 0.45 | 0.45 |

HT-PNCT-F Cable Parameter

| Number | Conductor | Thickness of Insulation | Thickness of Sheath |

Sheath Diameter | Weight | |

| Core x sq | Composition | Outer Diameter | ||||

| mm | Max./mm | mm | mm | mm | mm | kg/km |

| 3×10 | 0.26 | 4.8 | 1.1 | 2.1 | 13.0 | 670 |

| 3×16 | 0.26 | 6.0 | 1.2 | 2.3 | 15.0 | 930 |

| 3×25 | 0.26 | 7.4 | 1.2 | 2.5 | 17.5 | 1,290 |

| 3×35 | 0.26 | 8.7 | 1.2 | 2.7 | 18.0 | 1,650 |

| 3×50 | 0.26 | 10.4 | 1.5 | 3.0 | 21.0 | 2,290 |

| 3×70 | 0.26 | 12.5 | 2.0 | 3.4 | 25.0 | 3,250 |

| 3×95 | 0.26 | 14.5 | 2.0 | 3.7 | 27.5 | 4,170 |

| 3×120 | 0.26 | 16.2 | 2.0 | 4.0 | 30.0 | 5,090 |

| 3×150 | 0.26 | 18.2 | 2.0 | 4.2 | 32.0 | 6,150 |

| 3×185 | 0.26 | 20.2 | 2.5 | 4.6 | 36.0 | 7,710 |

| 3×40 | 0.26 | 23.3 | 2.5 | 5.1 | 40.0 | 9,900 |

| 3×300 | 0.26 | 26.0 | 2.5 | 5.4 | 43.5 | 11,990 |

| 4×10 | 0.31 | 4.8 | 1.1 | 2.1 | 12.5 | 870 |

| 4×16 | 0.31 | 6.0 | 1.2 | 2.5 | 15.0 | 1,300 |

| 4×25 | 0.31 | 7.4 | 1.2 | 2.7 | 17.0 | 1,790 |

| 4×35 | 0.31 | 8.7 | 1.2 | 2.9 | 18.5 | 2,290 |

| 4×50 | 0.31 | 10.4 | 1.5 | 3.2 | 21.5 | 3,160 |

| 4×70 | 0.31 | 12.5 | 2.0 | 3.7 | 25.5 | 4,470 |

| 4×95 | 0.31 | 14.5 | 2.0 | 4.0 | 28.0 | 5,720 |

| 4×120 | 0.31 | 16.2 | 2.0 | 4.3 | 30.5 | 6,980 |

| 4×150 | 0.31 | 18.2 | 2.0 | 4.6 | 33.0 | 8,450 |

| 4×185 | 0.31 | 20.2 | 2.5 | 5.1 | 37.0 | 10,690 |

| 4×240 | 0.31 | 23.3 | 2.5 | 5.6 | 41.0 | 13,650 |