The cable is designed with simultaneous tensile and torsional stress in mind, for applications under heavy mechanical stress such as Mobile, welding, mining, Special machine, Drum reeling, Crane, Hoist, hoppers, Stacker Reclaime, Elevator, Rail transit, Trailing Control, Marine, etc.

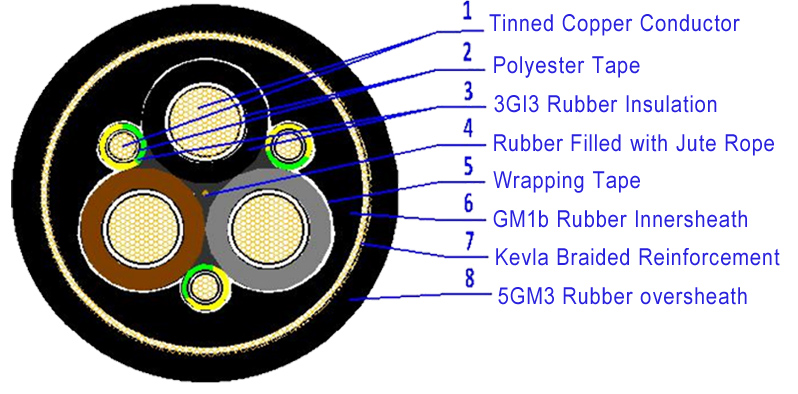

Round 0.6/1KV NSHTOU-J Overhead Crane Drum Reeling Cable

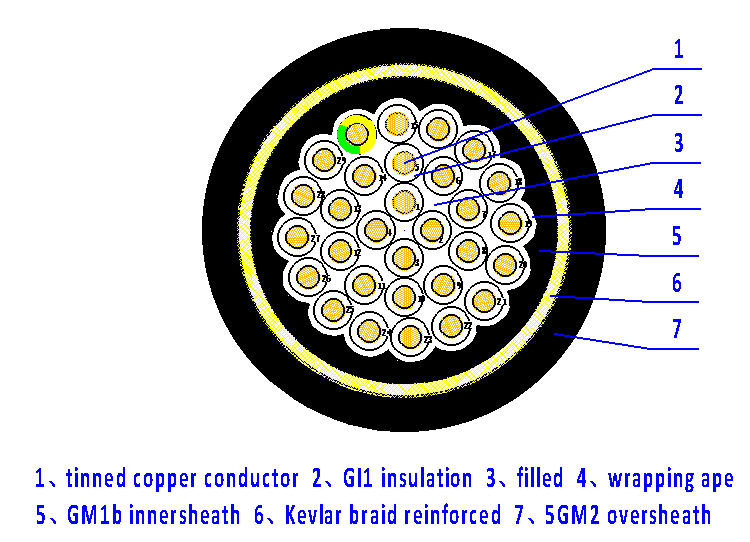

Conductor: Flexible Class 5 tinned copper conductor

Insulation: EPR-Type 3GI3

Core identification: 4 core: Green/Yellow Black Grey Brown

5 core: Green/Yellow Black Blue Brown Grey

above 5 cores & Order quantity below MOQ in White+number code.

Filler: Rubber-Type 3GI3

Inner bedding: Polychloroprene 5GM5

Reinforcement: Kevlar fiber braiding

Outer sheath: Polychloroprene 5GM5 Oil resistant and flame retardant

| Crane Cable Product | Application Overview |

| YSLTOE cable | Spreader cable for gravity-fed collector buckets |

| NSHTOU cable | Drum winding cable |

| (N)SHTOU cable | Drum winding cable with increased tensile strength |

| (N)SHTOU PUR cable | Drum winding cable with Polyurethane sheathing |

| (N)GRDGOU cable | Festoon cable |

| PUR-HF Festoon cable | Festoon cables including EMC protected cables |

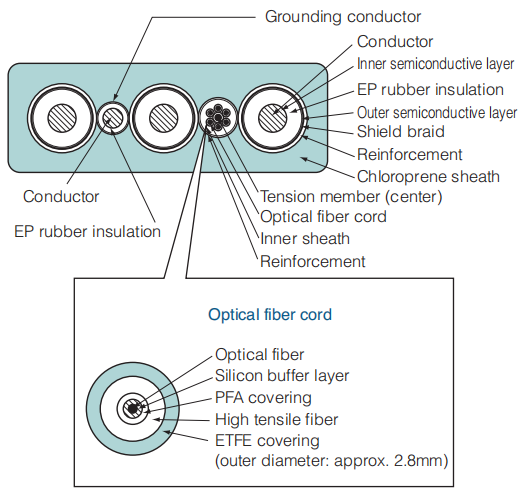

Flat Type Optical Composite Flexible Reeling Cable

Standards: Japan’s Technical Standards for Electrical Equipment

Rated Voltage: AC 3300V, AC 6600V

Rated Temperature: 80 degrees C

Test Voltage: 3300V rated: 9000V / 10 minutes ,6600V rated: 17000V / 10 minutes

Feature: High resistance to lateral pressure and bending

Application: Reel system (Traveling)

Standard core: Metal cores: white, green, red (optical), and blue

identification Optical cores: blue, yellow, green, red, purple, and white

Optical: (on completed cable)

Characteristic

-Permissible

-Tension

-Permissible Lateral

-Pressure

Round Type Optical Composite Flexible Rubber Reeling Cable

| No.of Cores | Conductor | Insulated Thickness | SheathThickness | ||

| size(mm2) | Construction(No/mm) | Outer Diameter(mm) | mm | mm | |

| 3×38+1×22+6 optical fiber core | 38 | 7/34/0.45 | 9.1 | 5 | 5.7 |

| 22 | 7/20/0.45 | 7 | 1.6 | ||

| 3×50+1×30+6 optical fiber core | 50 | 19/16/0.45 | 10.4 | 5 | 5.9 |

| 30 | 7/27/0.45 | 8.1 | 1.6 | ||

| 3×60+1×30+6 optical fiber core | 60 | 19/20/0.45 | 11.6 | 5 | 6 |

| 30 | 7/27/0.45 | 8.1 | 1.6 | ||

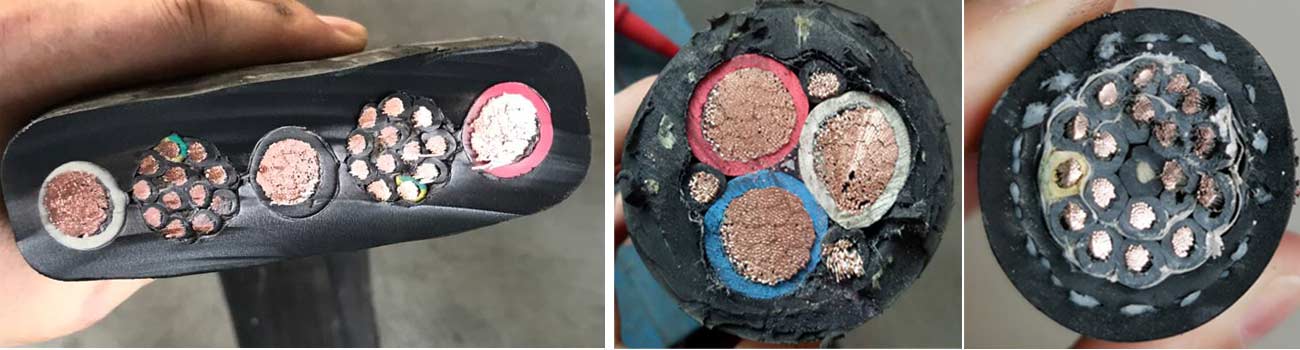

Heavy-duty NSHTOU PUR Mining Rubber Trailing Cable

Nominal voltage: 0.6/1KV

Test voltage: 2500 V

Temperature range:

flexing -35°C to +70°C

fixed installation -40°C to +70°C

max. Temperature at conductor

in operation +60°C

in short-circuit +200°C

Minimum bending radius

7,5 x cable Ø

Radiation resistance

up to 20×106 cJ/kg (up to 20 Mrad)

Application of Trailing Cable

Trailing cables are used for high mechanical stress, especially for applications with frequent winding and unwinding with simultaneous tensile and torsional stress, for building machinery, conveyors, shifts, and cranes. They are used as robust and all-weather resistant cables of roughest operations in mining and inflexible handling equipment and railway motors.

The cables are suitable for outdoor installation in dry, damp, and wet places as well in the open air. For applications that go beyond standard solutions, we recommend that you fill out our specially developed questionnaire for reeling cables. Please read the installation instructions.

PUR SHTOU Rubber Mining Trailing Cable Parameter Data

| AGW-No. | No.Corexcross-sec. | Outer. Ø | Cop.Weight |

| mm2 | app.mm | kg/km | |

| 12 | 4G 4 | 18.5 | 158 |

| 12 | 5G 4 | 21.5 | 220 |

| 10 | 4G 6 | 21 | 241 |

| 10 | 5G 6 | 23.5 | 317 |

| 8 | 4G 10 | 26 | 404 |

| 8 | 5G 10 | 28 | 508 |

| 6 | 4G 16 | 29 | 642 |

| 6 | 5G 16 | 31.5 | 768 |

| 4 | 4G 25 | 35 | 1005 |

| 2 | 4G 35 | 37.5 | 1344 |

| 1 | 4G 50 | 44.5 | 2010 |

| 2/0 | 4G 70 | 49 | 2688 |

| 3/0 | 4G 95 | 56 | 3648 |